3 min read

How to Diagnose Equipment Quickly and Accurately For Effective Maintenance Diagnostics

ATP

Sep 29, 2016 5:39:00 AM

Elon Musk, founder of Tesla, PayPal and SpaceX was interviewed by Kevin Rose on the web-series Foundation, a show that interviews well-known entrepreneurs in the tech industry. When asked what advice he would give new entrepreneurs, Musk emphasized the importance of starting to analyze opportunities using first principles rather than analogy (i.e., what is known to be true rather than what appears to be true based on past experiences).

Just as evaluating a business opportunity requires an understanding of the underlying business principles, the same is true for diagnosing equipment defects where effective repairs require an understanding of the underlying failure modes. Without understanding how the equipment is supposed to operate and how components interact with one another it is difficult to diagnose and repair a problem (i.e., what each symptom means by itself, and in combination with other symptoms).

Effectively Diagnosing Equipment Using First-Principles and Analogy

Unfortunately, many repairs get started based on analogy (prior experience) before the technician understands all of the symptoms, which harms the cost, quality and time of the repair. However, once the first principles (symptoms) have been understood, prior experience plays an important role for efficient repairs, especially when different defects have similar symptoms. ATP’s SpotLight® troubleshooting solution optimizes equipment diagnosis by leveraging both first principles and analogy, which is especially useful for troubleshooting complex systems where unexpected symptoms are quite common.

Today, service organizations are struggling with the loss of experienced technicians who have a firm understanding of equipment operations and failure modes. Without that deep knowledge, novice technicians struggle to deliver the same results. Therefore, service organizations are looking for ways to capture and reuse the thought processes, best practices, tips, and tricks of their most experienced technicians, which is the key to effective diagnosis and repair.

The goal of diagnosis is to accurately identify equipment problems as quickly and economically as possible so the defect can be fixed on the first try, with the fewest parts, in the shortest time. First-principles for diagnosis would analyze equipment operating conditions, performance fluctuations, error codes, etc., in order to produce a list of possible failure modes. An expert technician would then use subjective evidence (analogy) based on previous experience to further isolate the specific cause of a problem (i.e., sights, sounds, smells, repair history, adjacent system data, etc.). The combination of first principles and analogy ensures technicians recognize which components and failure modes are generating the reported symptoms, so they can fix it.

How The Spotlight Solution Streamlines Diagnosis

SpotLight employs Musk’s philosophy of first principles but it also uses analogy, based on anecdotal evidence from previous repairs that have been captured within its diagnostic database. Rather than relying on a traditional decision tree approach, which follows a specific troubleshooting sequence, SpotLight uses a diagnostic database containing both types of data (first principle and analogy) to help technicians gather relevant bits of information that uniquely identify the cause of the problem, improving diagnostic accuracy and reducing equipment down time and cost.

In practice, Spotlight delivers a customized troubleshooting process for each diagnostic situation and technician, regardless of their level of expertise (from novice to veteran). SpotLight starts by collecting first principle data about the equipment and supplements that with subjective information from equipment operators and technicians, to quickly isolate the cause of the problem. This approach accounts for the specific behavior of each component as well as cross-system effects, to clearly identify early the equipment that requires diagnostics, maintenance, or repair. SpotLight is far more efficient and reliable than traditional fault isolation manuals and knowledge portals because the sequence of data entry (telematics, questions and answers) does not influence the final diagnosis.

Effective equipment maintenance diagnostics and repair is critically important to equipment operators and while speed is almost always an issue, diagnostic accuracy should be the critical concern for everyone involved. Starting from first principles may seem tedious to experienced technicians but any other approach runs the risk of being corrupted by hidden assumptions that result in poor quality, higher costs and longer delays. By adopting and adapting Musk’s approach, SpotLight narrows down equipment issues using first principles and field experience (analogy) to quickly and accurately isolate equipment defects.

About ATP.

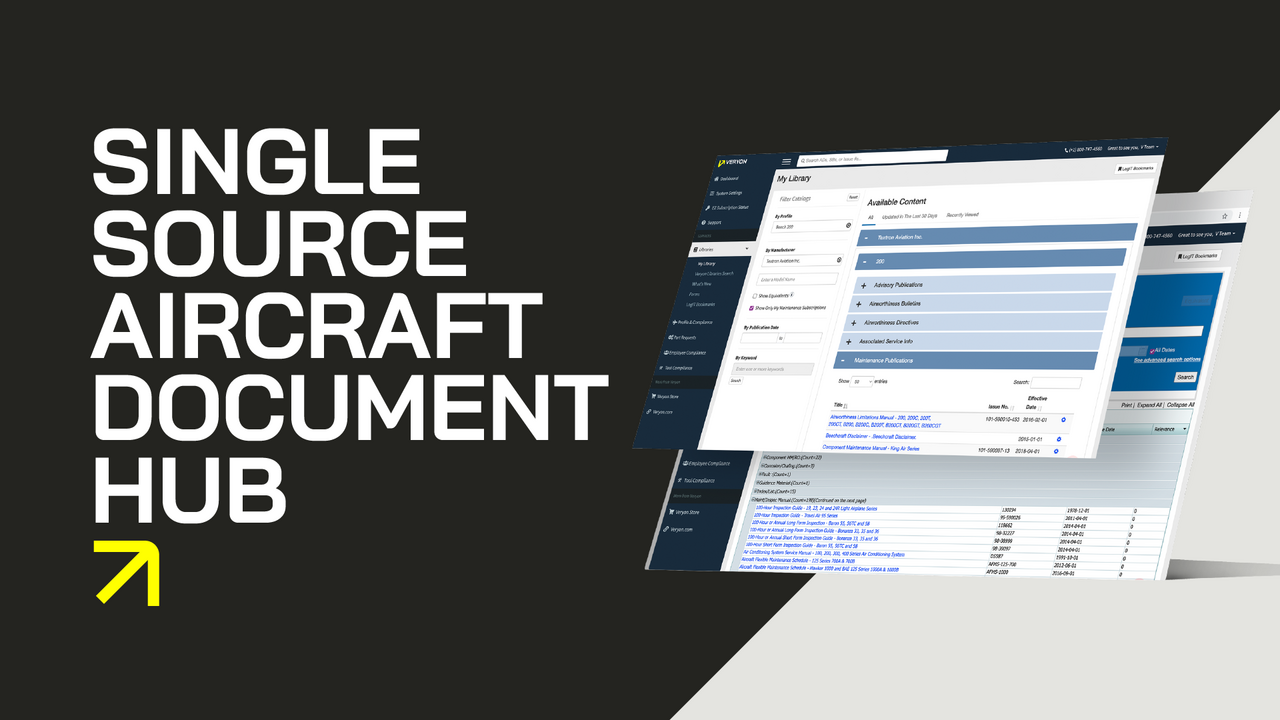

ATP is the leading provider of aviation software and information services.

Our innovative product lines, including Flightdocs, Aviation Hub, ChronicX, and SpotLight, reduce operating costs, improve aircraft reliability, and support technical knowledge sharing and collaboration in all aviation and aerospace industry sectors.

The products and services of ATP support more than 75,000 aircraft maintenance professionals worldwide. As a global company, ATP has more than 7,500 customers in 137 countries and partnerships with over 90 OEMs.